Flower Processing

In the highly competitive floriculture industry, efficiency, consistency, and quality are crucial to success. One of the most impactful innovations in this field is the adoption of flower processing lines automated systems designed to streamline the post-harvest handling of cut flowers. These systems offer substantial advantages, particularly in terms of economic savings and enhanced quality of flower bundles. Below is a comprehensive overview of the key benefits of integrating a flower processing line into commercial flower operations.

Flower Processing Lines for every grower & flower wholesaler

Whether you're running a high-volume export operation or a smaller local flower farm, we have the perfect solution to optimize your post-harvest process and flower logistics. Our two flower processing lines are designed to match your scale, needs, and budget without compromising on quality.

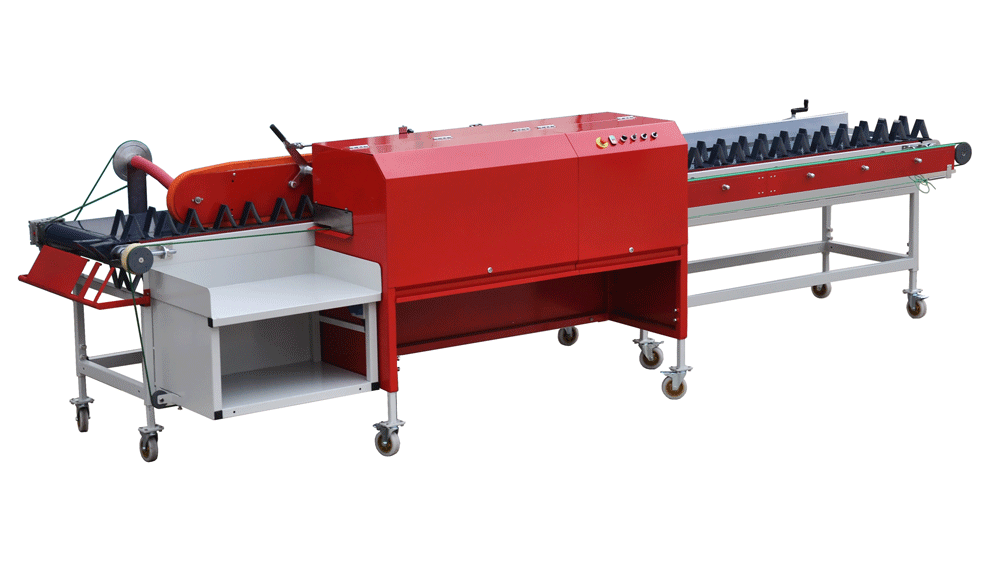

BTM Flower Processing Lines

Premium Line – More options & PLC control

Ideal for: Exporters, industrial greenhouses, and growers with high processing volume and demand for precision.

Key Benefits:

- Fully automated trimming, sorting, and bundling

- High-speed operation for maximum daily output

- Advanced controls and programmable settings

- Consistent, professional-quality flower bundles

- Minimal manual handling – reduced labor costs and improved hygiene

Why Choose It?

If your business relies on large-scale efficiency and flawless presentation, our high-end line delivers unmatched productivity, uniformity, and long-term reliability. A smart investment for professional floriculture.

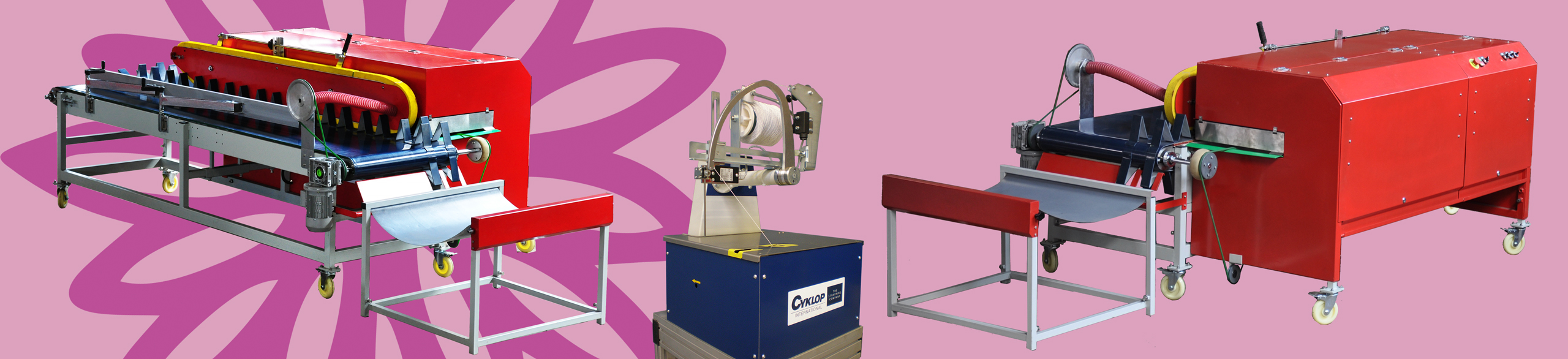

FlowerHands Processing Lines

Basic Line – Affordable Efficiency

Ideal for: Small farms, seasonal growers, startups, or budget-conscious operations.

Key Benefits:

- Reliable trimming and bunching performance

- Easy to operate and maintain

- Compact design for smaller workspaces

- Significantly reduces manual labor and time

- Great value with low upfront investment

Why Choose It?

Our low-cost basic line offers all the essential features needed to improve productivity and flower quality without the complexity or cost of a full-scale system. Perfect for growers ready to scale up with confidence.

Economic Advantages

-

Labor Cost ReductionOne of the most immediate and tangible benefits of a flower processing line is the reduction in manual labor. Traditional flower bundling and trimming require multiple workers for cutting, bunching, measuring, and wrapping. A processing line automates many of these steps, allowing growers to reduce staffing levels or reassign labor to more value-added tasks. Over time, this results in significant cost savings.

-

Increased Throughput and ProductivityAutomated processing lines can handle a far greater number of stems per hour than manual labor. This higher throughput means that growers can process more flowers in less time, increasing the overall capacity of their operation. This is particularly advantageous during peak seasons when speed is essential to meet market demand without sacrificing quality.

-

Reduction of Waste and ShrinkageWith consistent cutting lengths and calibrated bunch sizes, processing lines minimize waste. This not only reduces the cost of discarded materials but also ensures that every flower stem contributes to a marketable product. Additionally, automation reduces handling errors and mechanical damage to the stems, further decreasing loss.

-

Better Inventory Management and PredictabilityA standardized processing method allows for more accurate forecasting, packing, and shipping. With reliable outputs, growers can commit to orders with greater confidence and minimize last-minute surprises that could disrupt the supply chain.

Quality Improvements to Flower Bundles

-

Consistency and UniformityManual flower handling can result in inconsistent stem lengths, irregular bunch sizes, and uneven trimming. A processing line ensures that every flower bundle meets predetermined specifications for size, shape, and appearance. This consistency is highly valued by wholesalers and retailers, as it enhances the visual appeal of the product and supports uniform pricing.

-

Enhanced Presentation for RetailWith automated wrapping, labeling, and bundling, flowers arrive at their retail destinations in a polished, market-ready condition. This professional appearance not only helps attract customers but also reduces the need for additional preparation at the point of sale.

-

Faster Cooling and Transport ReadinessBecause the processing line speeds up the post-harvest process, flowers can be cooled and packed more quickly. This rapid transition from harvest to cold storage helps preserve bloom integrity and prolong vase life—an essential factor in maintaining customer satisfaction.